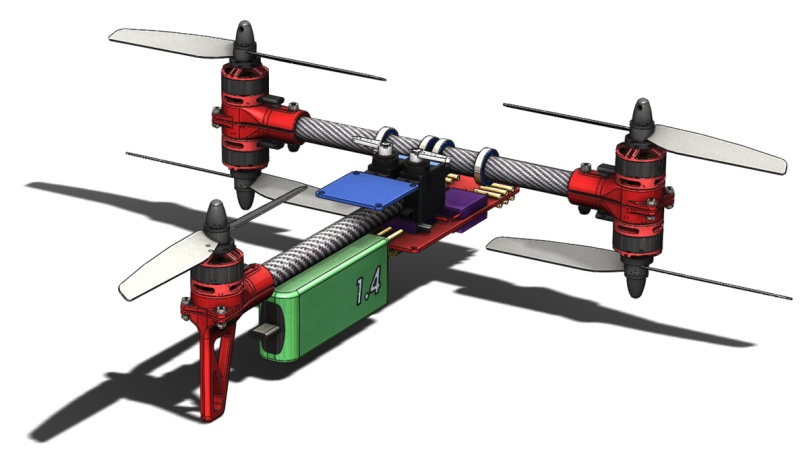

Having reached a stage where I am happy with the general structure of the two core chassis pieces I thought it time for an update. Shown here is the lower half of the structure with the servo module nestled in the middle.

I have not yet added the belt tensioning mechanism but the intention is for a screw to be inserted through the front face of the chassis to push on the servo carrier.

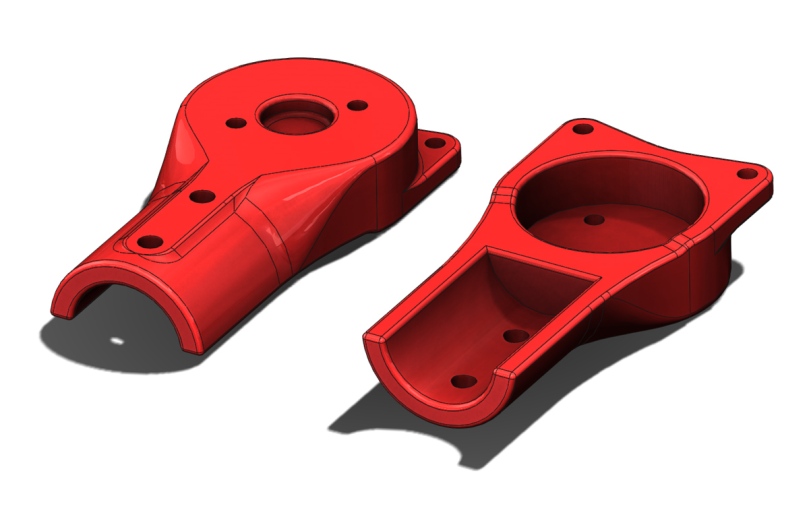

This is how the lower chassis piece appears in isolation. There is still plenty of refinement to follow including weight reduction (only where significant gains can be made given that this is primarily a proof of concept) and rounding of sharp corners. The upper half is a direct copy of this piece for the bearing supports and servo mounting but the rear end changes to make space for the flight controller.

Whilst the flight controller was on my mind a made a point of checking pin locations on the intended board (The RMRC Seriously Dodo Flight Controller). My plan of attack is to mount the board with the USB connector facing rearward and then install 90° pins backwards on to the outputs, that is to say so that the connectors and wires will run across the board rather than away from it as would usually be the case.

I have also attended to the positioning of the receiver I will be using, the FrSky X4R (my RX of choice due to its S.Bus and SmartPort interfaces). As shown here it will be on the front of the chassis (behind the nose cone).

Whilst working on the chassis pieces I also added mounts for the antenna. By no means are they optimised for diversity, I am not expecting reception issues given I will only be flying this with direct line of sight.

There are still a lot of fine details to attend to but hopefully with some time away from work during the holiday period I will be able to get all the 3D printed parts buttoned down and out for printing (no printer in house unfortunately).