I finally have the design of the 215 Hopper at a point where I think it is fit for purpose as an FPV copter. It can now sustain a heavy grounding without terminal damage. I still won’t claim that it is as durable as a carbon plate design but I am now happy to release it. The camera pod is perhaps the least durable part of the design however I am still flying with the first one I printed and it has served its purpose protecting the flight cam. I do intend to upgrade it at some point but that will probably come after the custom camera pod for my Shendrones Tweaker.

If you’re interested in building a 225 Hopper FPV then you can find all the files you will need over at Thingiverse

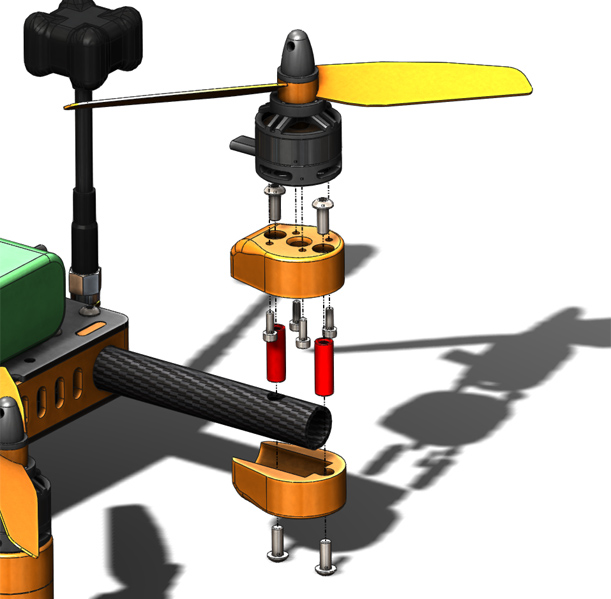

I have made 2 changes to the previously seen FPV design iteration to realise these durability improvements. Firstly I scrapped the idea of running the motor wires through the arm tubes. Whilst I think this still has merit, for now it was causing more problems than it was solving. I will perhaps look at it again in the future. I have however maintained a similar motor mounting arrangement. All 4 M2 threads are used to attach the motor to the top half of the motor mount with the motor wires aligned with the arms. Separate bolts are used to clamp the motor mount to the arm tubes.

The second change is specifically to do with the clamping bolts on the motor mounts. Now rather than simply clamping on to the tube end and relying on friction to keep it in place I have created a positive interaction between tube and mount.

As seen in this exploded view of the motor mount the tubes are now drilled with a 5mm hole to accept the same 15mm M3 standoff that is used throughout the rest of the frame build. The 2 printed parts of the motor mounts then snap over these standoffs and are clamped together with M3x8 button head screws. The only trick to this is that the standoffs must be screwed in to the top half of the mount before the motor is subsequently mounted to that before it is finally installed on the arm.

At the same time as making these motor mount changes I decided to keep things simple and remove the LED tail lights. Now the same 2 parts are used at all 4 corners. Speaking of parts, the image below shows all the parts required to build the 215 Hopper FPV edition.

Included are (in order from left to right, top to bottom):

- 2x 215H 101 12mm x 10mm x 183mm Carbon fiber arms

- 1x 215H 107 Top plate PDB

- 2x 215H 106 Bottom plate

- 4x 215H 138 Motor mount bottom

- 4x 215H 137 Motor mount top

- 1x 215H 103 Frame side

- 1x 215H 111 Frame side with USB access

- 3x 215H 108 Tube clamp

- 1x 215H 102 Tube clamp with antenna mount

- 1x 215H 130R Camera pod right side

- 1x 215H 130L Camera pod left side

- 1x 215H 126 Video Tx pod

- 2x 215H 134 Camera pod spacer

- 1x 215H 132 Camera pod rear post

- 1x 215H 133 Camera pod front post

- 1x 215H 131 Camera pod base plate

- 18x M3x15 Round standoff

- 2x M3x20 Round standoff

- 40x M3x8 Button head socket screws

- 4x M3x10 Nylon screws

- 8x M3 Nylon nuts

All the 3D printed parts are printed in ABS with a 30% infill, 3 outlines, 3 solid bottom layers and 4 solid top layers. Colour is unimportant but I find it looks its best if the frame parts are a bright colour (as seen here in orange or previously in red) and the accessory parts are black.

The 215 Hopper FPV is designed around a fairly specific set of components. This is not to say that other parts won’t work on the frame but rather that the positions and space allocation work best with what I have used. My recommended build uses:

- DYS 1806-2300kV motors

- 18A ZTW 18A Spider series Opto ESC’s

- Naze32 Rev 6

- 25mm Plastic housing FPV camera such as the HS117 or HS1189

- Lumineer TX5G8 Pro power switch vTx

- FrSky X4R-SB receiver

- Pololu 5v converter

- 5cm 90° bulkhead SMA extension

An important detail to note when assembling the frame is that the flight controller should be in the front half of the craft. The reason for this, as I noted on a previous post, is that the vTx pod must fit around the nylon screws used for mounting the flight controller. There are holes specifically for this purpose in the pod. Another new feature on the vTx pod is the inclusion of the slot seen below. This allows you to see what band and channel is selected on the vTx and also if it is transmitting or not. This small details makes working with this specific transmitter significantly less frustrating.

A lot of the notes I made regarding the initial build (found here) also apply to putting together this FPV version. In lieu of a full write up for this I will direct you to that if your would like to build one for yourself. Also please feel free to contact me or leave a comment here with any questions that you might have.

There are a couple of build notes that do specifically need to be made for this model:

- Whilst not strictly necessary I solvent welded the 3 parts of the camera mount together (parts 131, 132 and 133). Durability has exceeded my expectations so that is probably a worthwhile step to take.

- As I have left over PCB’s from my first batch I have not modified the bottom board to include a hole for passing the vTx wiring. You will need to drill this just in front of where it will connect to the vTx. It should end up just inside the ‘mouth’ of the pod.

- As the motors are now fixed to the tubes drilling the holes through which the mounts pass is critical. They must be aligned end to end. For this I have included part 215H 139 which is a drilling jig. Print two and slide one on to either end of the arm tube. You can then use the flat sides for alignment. I suggest holding the jig with a clamp or vice whilst drilling as the thin wall carbon has a tendency to grab onto the drill bit.

If you decide to build one i would love to see it! let me know about it here or post it up as a build on thingiverse.