At the end of last week I found myself at the intersection of 3 lines of thought:

- What could I transfer the flight systems on my Spidex220 to for a more rigid platform.

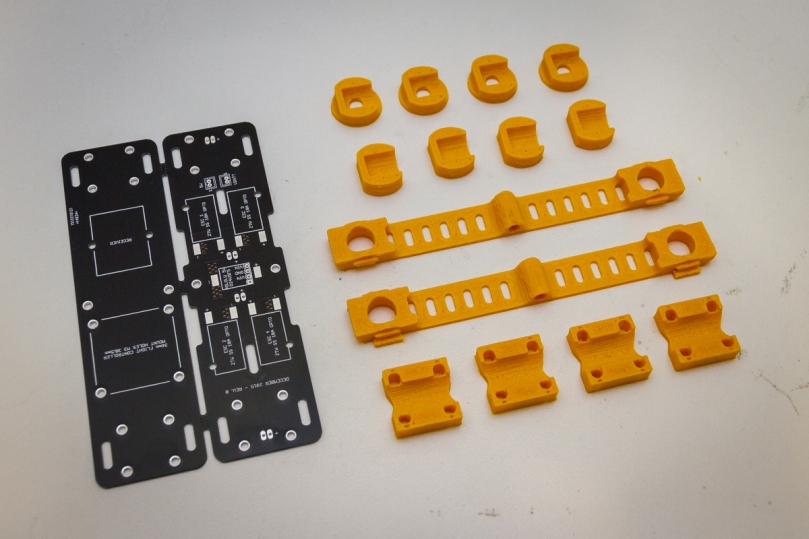

- A friend has a FDM style 3D printer. I have reservations about the tolerances achievable with it for printing the finer parts of the MultiChase Project (which has always been designed with SLS printing in mind). What can I do to involve him and his printer.

- How quickly I can come up with a viable solution to 1 and 2.

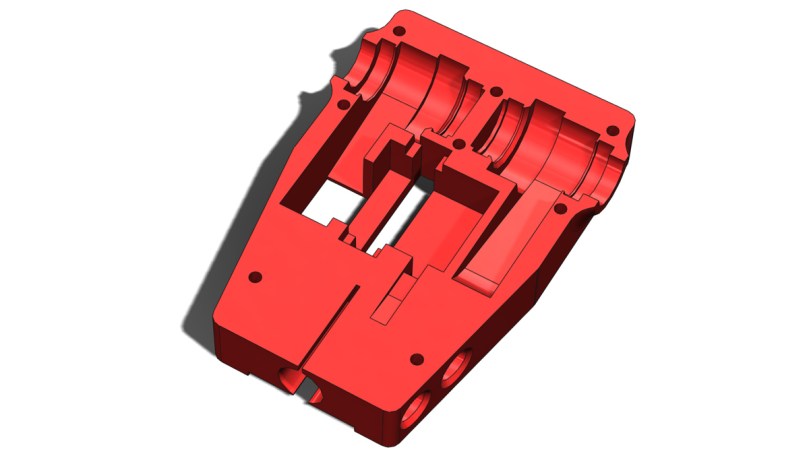

These thoughts have resulted in a speed challenge of sorts for myself. I have decided to come up with a simple quad that I hope will be printable on a basic FDM printer. I’ve not got any hands on experience with the equipment but I figure if I keep the design simple and the tolerances forgiving then I can’t go too far wrong. I don’t want to divert too much time away from the MultiChase Project hence the speed challenge.

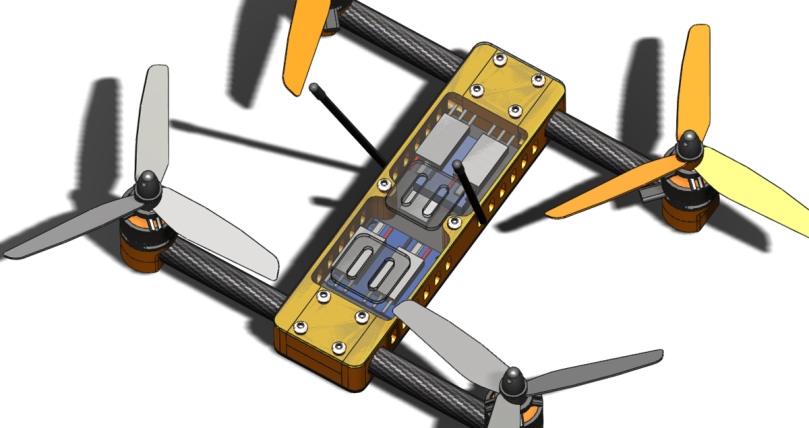

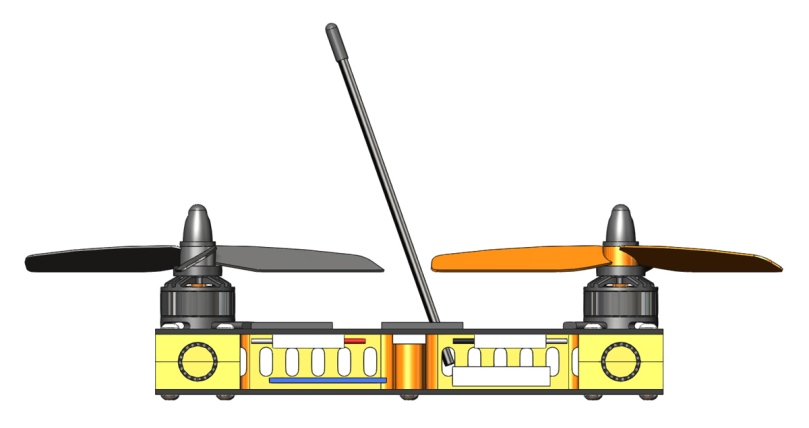

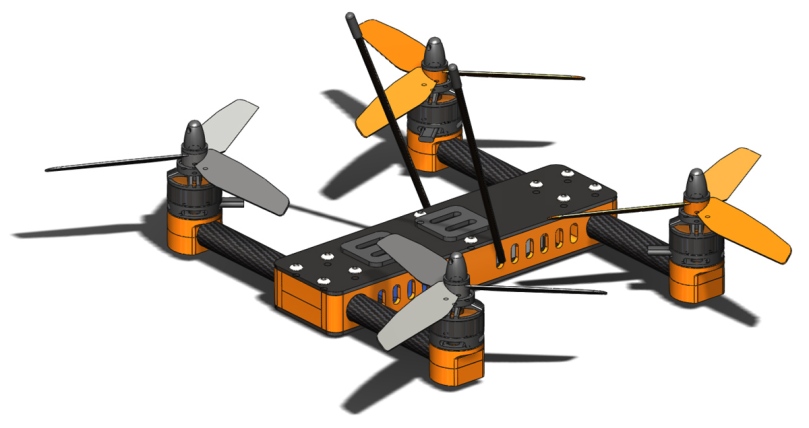

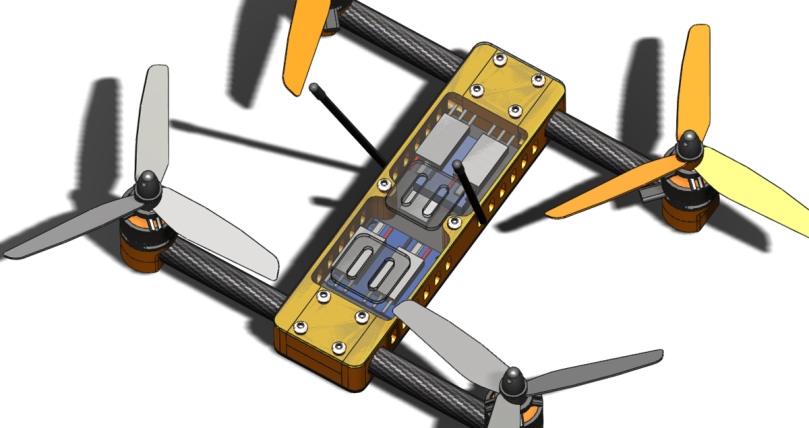

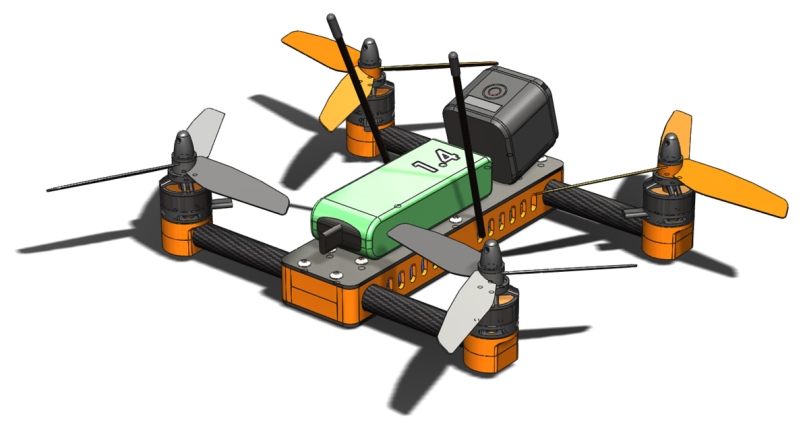

After 3 hours work spread over 3 sessions I have come up with the framework for the solution. The motor spacing is slightly smaller than the Spidex220 I will be cannibalizing. Motor spacing is 215mm as hinted at by the name I have given it, 215 Hopper.

The design is heavily inspired by the Flite Test VersaCopter. The layout is basically identical only it is much more compact and uses 3D printed parts rather than laser cut plates. Hopefully with more material supporting the tubes durability will be better.

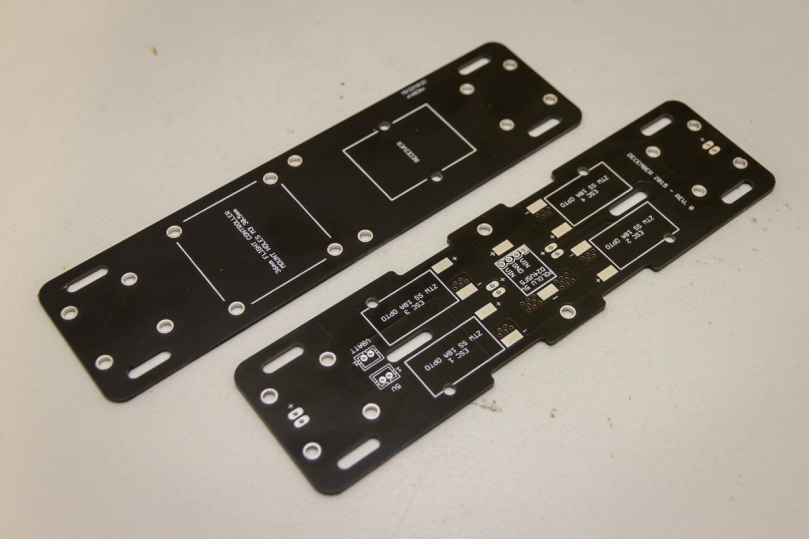

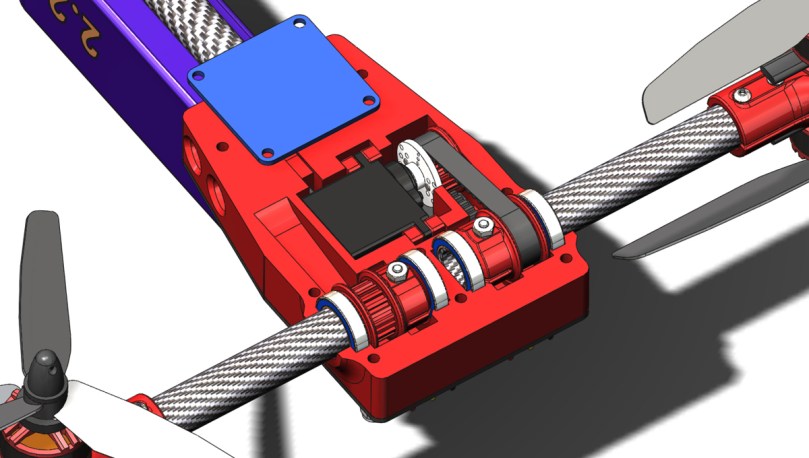

All of the flight electronics, including the ESC’s are carried inside the chassis. ESC’s will be attached to the top panel (and power distribution board), whilst the flight controller, 5v regulator and receiver will be on the bottom panel.

The ESC’s I have been using in the Spidex220 have not inspired a lot of confidence, often exhibiting inconsistent performance. As such it took very little for me to decide to try something else. When they didn’t quite fit the width I was targeting they were dropped in favour of a different design, the ZTW Spider Series 18A Opto Lite‘s. The lack of a BEC on this ESC has necessitated the inclusion of a 5v regulator to power the flight controller and receiver.

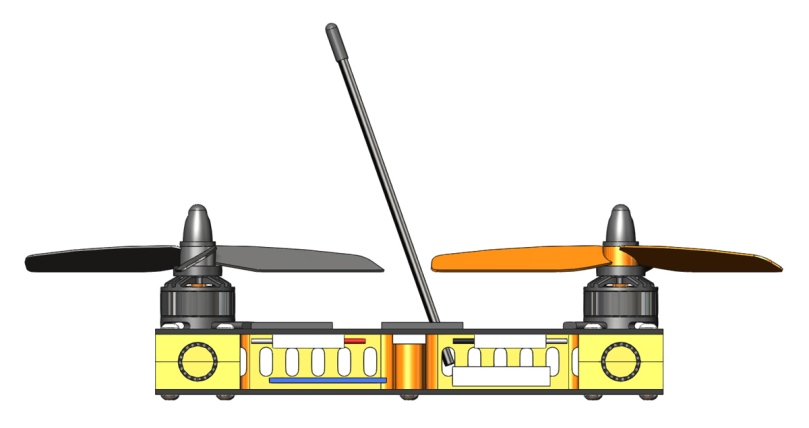

In isolation the 215 Hopper will look like this.

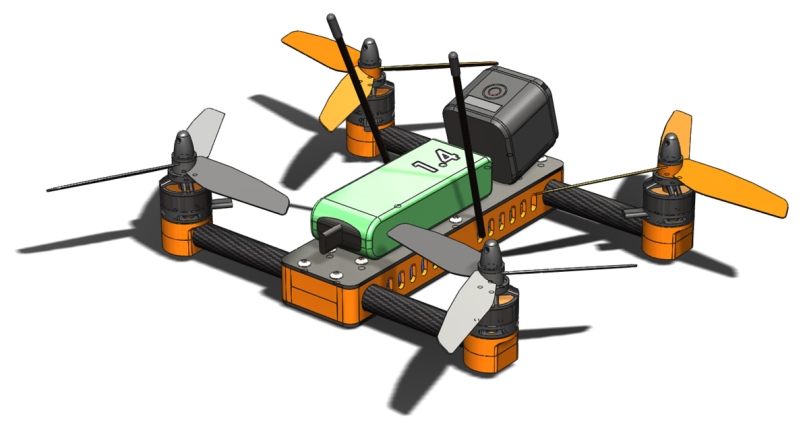

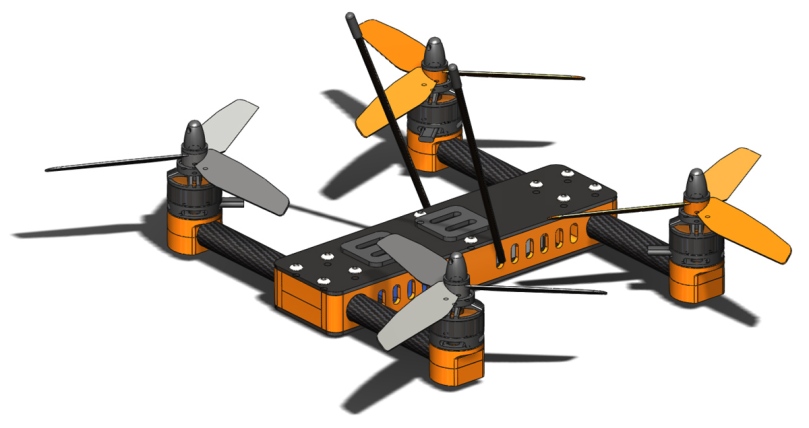

With the battery, a 1400mAh Multistar LiPo (3S shown but I might get some 4S packs if everything works out), and a GoPro Session on board a real sense of scale hits me in the face. Its very compact! As hinted at by the presence of the GoPro I hope to add FPV hardware in the future however I am not designing with that as a requirement.

There is still some detail to work out on the side plates and I need to design some clip in antenna tube mounts. Once that is sorted I will make another post showing the assembly detail and it will then be ready for printing. On the time front, the quoted 3 hours is exclusively CAD time. I have spent probably that much again looking for and purchasing various bits of hardware to make this happen but I am quite pleased with progress.