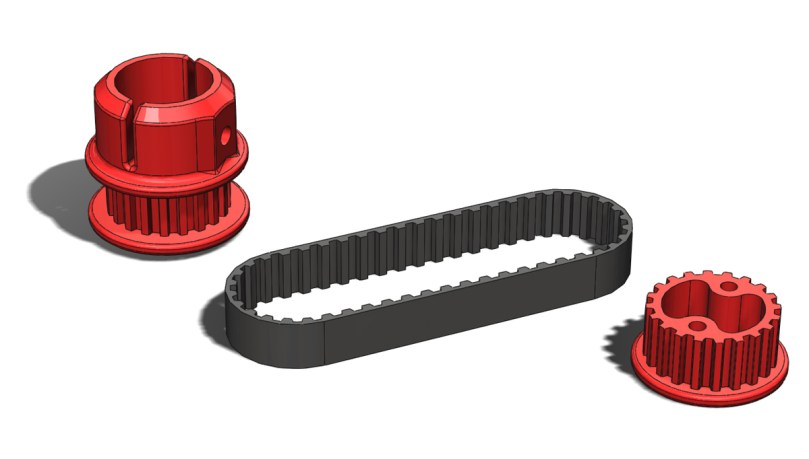

After looking at the range of motion that was going to be achievable with the previously shown boom control arms I was dissatisfied. Only about 70° was realistic. As a rough goal I would like to achieve 135° (90° forward and 45° backward). To get this range of motion and maintain a compact envelope I have decided to investigate the use of a belt drive system. Shown below is the layout I have come up with. The servos are laid on their side and stacked on top of each other and custom pulleys are used at both ends. It may be possible to source a pulley to fit the servo directly but at this stage I have not come across a source so I intend to pursue a 3D printed pulley attached to a standard round horn.

The power distribution philosophy has also seen some development. Primarily I have split the ESCs onto separate top and bottom boards. These boards will also serve as sandwich plates on the outsides of the internal structure (supporting bearings, servos etc.). I’ve also decided to forgo the use of board mounted bullet connectors and instead solder the motor wires either directly to the ESCs or onto the power distribution boards. I learnt from the construction of the Spidex 220 that this is really not as much of a complication as I had imagined it might be. The extra board real estate also opens up a good spot for the XT60 connector, the battery wire would loop around and in on itself to connect.

All together this creates a fairly tall stack height. As I develop the conceot further I hope to find ways to minimise it.